Transmission of signals and radio frequency (RF) in the multi-megahertz range frequently uses RF coaxial cables/RF cable assemblies. Depending on the intended usage or application, FLU-TEF WIRES & CABLES PVT. LTD. can construct coaxial cable assemblies with a variety of connectors and cable types in a range of lengths. RF cable assemblies are another name for coax cable assemblies. We are manufacturing flexible & semi rigid cables with PTFE dielectric & FEP/ PTFE jackets.

Our best knowledgeable technical staff can provide suggestions for product enhancements as well as assistance with the choice of RF coaxial cablesUL. The central conductor, which is typically made up of a single solid copper wire, is used in the actual design of the coaxial cable assembly to transfer electrical signals. The solid copper wire is encircled by a woven metal braid and covered in an insulating layer. Coax virtually avoids magnetic and electric leakage by design. There is little leakage outside the braid and these fields are contained within the dielectric. Due to FLU-TEF WIRES & CABLES PVT. LTD. very minimum order requirements and expert engineering design services, we are able to produce customised coaxial cable assemblies and RF cable assemblies to meet the requirement of the customer and application.

High Power RF Cable Assemblies and Coaxial Cable Assemblies

Each RF cable assemblies and coaxial cable assemblies, we manufacture is tailored to the needs of the customer. At FLU-TEF WIRES & CABLES PVT. LTD., we take pride in the RF / coaxial cable assemblies’ quality, delivery, and price as well as our solid client reputation.

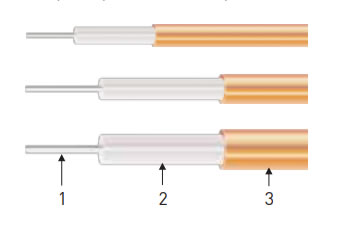

Contruction

- 1Solid conductor made up of

- Silver plated copper clad steel (SCCS) or

- Silver plated copper (SPC)

- 2 Dielectric layer of solid extruded PTFE.

- 3Outer conductor made up of Deoxidized & annealed Electrolytic Bare or Tin or Silver or 90/10 Tin-lead plated copper tubing

Operating Temperature: -40°C to + 125°C

These cables are designed for Super High Frequency connection up to 20GHz.

SEMI RIGID Coaxial cables are manufactured as per JSS 6145-24/MIL-DTL-17J and their respective MIL datasheet.

Characteristics of Semi Rigid Cables

In order to constantly meet technical, precision, and quality standards, we aim to combine market-leading signal integrity expertise with premium RF solutions. SEMI RIGID cables are produced in accordance with MIL-DTL-17J, JSS 6145-24, and the corresponding MIL datasheet.

- 100% filtering, providing superior interference protection.

- Simplicity in stripping, soldering, and joining.

- The minimum recommended bending radius is three times the cable's diameter.

- Vacuum has no outgassing.

Applications

Assembly manufactured with customised cable length depending on the configuration (male (plug) to male, female to male, or male to female), orientation (straight, right-angle), and mounting (bulkhead). These traits and distinctive design elements enable standard groups to meet the specific design needs of various applications across markets.

- Transmission and delay lines for microwaves

- Calculator with a high processing speed and a low noise amplifier circuit.

- Connectors that are perfectly screened and suitable for aircraft applications.

- Applicable with waveguides.

- Modernization of internal module connections technology.

- Strong vibrational stress resistance and high phase stability.

To ensure that each RF / coaxial cable assembly is produced correctly and performs as intended, FLU-TEF's Quality Control Department can conduct physical and electrical testing. Please contact our qualified personnel for any additional questions regarding wiring and cable.

| Flu-Tef Part No |

Reference MIL Part No |

Inner Conductor n x mm |

Conductor Diameter mm |

Dielectric Core mm |

Outer Conductor Copper Tubing |

Over all Diameter mm |

Weight Kg/Km Max |

|---|---|---|---|---|---|---|---|

| F401 F401T |

M17/129RG401 M17/129-00001 |

1 x 1.628 SPC 1 x 1.628 SPC |

1.628±0.025 1.628±0.025 |

5.30±0.05 5.30±0.05 |

Bare Copper Tin Plated coppe |

6.35±0.05 6.35±0.05 |

156.24 157.73 |

| F402 F402T |

M17/130-RG402 M17/130-00001 |

1 x 0.92 SCCS 1 x 0.92 SCCS |

0.92±0.018 0.92±0.018 |

2.97±0.025 2.97±0.025 |

Bare Copper Tin Plated copper |

3.58±0.025 3.58±0.025 |

51.18 52.23 |

| F405 F405T |

M17/133-RG405 M17/133-00001 |

1 x 0.51 SCCS 1 x 0.51 SCCS |

0.51±0.013 0.51±0.013 |

1.68±0.05 1.68±0.05 |

Bare Copper Tin Plated copper |

2.20±0.025 2.20±0.025 |

22.76 23.51 |

| Flu-Tef Part No |

Impedance Ohms |

Capacitance pf/Mtr Max |

Operating Frequency GHz Max |

WorkIng Voltage Volts RMS |

Attenuation dB/100 Mtrs, Maximum |

Power rating Watts, Maximum at GHz |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Structural Return Loss dB Minimum at GHz |

||||||||||||||||

| 0.1 | 0.4 | 1.0 | 3.0 | 10 | 20 | 0.4 | 1.0 | 3.0 | 10 | 18 | 20 | |||||

| F401 | 50±0.5 | 97 | 18 | 3000 | - | 14.8 | 24.6 | 52.5 | 108.2 | 18G-157.5 | 1900 | 1400 | 750 | 350 | 200 | -- |

| 19 | 18G-16 | |||||||||||||||

| F401T | 50±0.5 | 97 | 18 | 3000 | - | 14.8 | 24.6 | 52.5 | 108.2 | 18G-157.5 | 1900 | 1400 | 750 | 350 | 200 | -- |

| 19 | 18G-16 | |||||||||||||||

| F402 | 50±1 | 98.1 | 20 | 1900 | 13 | 26 | 39 | 69 | 148 | 230 | 600 | 450 | 250 | 120 | -- | 70 |

| - | - | 28.5 | 24.6 | 22.2 | 20.6 | |||||||||||

| F402T | 50±1 | 98.1 | 20 | 1900 | 13 | 26 | 39 | 69 | 148 | 230 | 600 | 450 | 250 | 120 | -- | 70 |

| - | - | 28.5 | 24.6 | 22.2 | 20.6 | |||||||||||

| F405 | 50±1.5 | 105 | 20 | 1500 | - | 40 | 72 | 123 | 262 | 427 | 180 | 130 | 74 | 35 | -- | 20 |

| - | - | 27.5 | 25.5 | 20 | 15 | |||||||||||

| F405T | 50±1.5 | 105 | 20 | 1500 | - | 40 | 72 | 123 | 262 | 427 | 180 | 130 | 74 | 35 | -- | 20 |

| - | - | 27.5 | 25.5 | 20 | 15 | |||||||||||