Electrical shielding may be required while creating an electrical harness or loom in order to carry electrical signals with the least amount of noise. FLU-TEF WIRES & CABLES PVT. LTD. produces a variety of Metal Braids for this use. To facilitate application and use, it can be provided with or without a flexible plastic preform. It keeps its original spherical form.

Diameters from 3 to 40 mm are available in standard sizes. The finish possibilities for the conductor will be silver, nickel, or tin depending on how it will be utilised in various temperature conditions. They can be used with common connectors. We can provide any custom size. Copper wires that have been silver, tin, or nickel-plated form a tubular braid. In accordance with MIL specification A-A-59569B, the cover factor is approximately 90%.

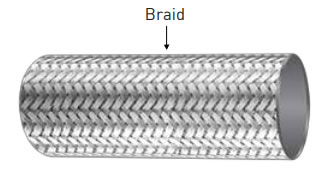

Contruction

Tubular braid made up of silver /Tin/Nickel plated copper wires The cover factor is about 90 % according to A-A-59569B MIL specification

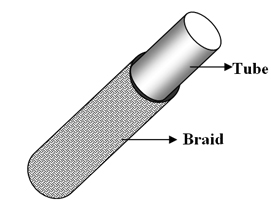

Braids are also available with central filler to prevents deformations of braid

| Part No. | Internal diameter D Nominal mm |

Tolerance on internal Diameter mm ± |

Diameter of each strand mm |

| FBS02x | 2 | 0.30 | 0.13 |

| FBS03x | 3 | 0.50 | 0.13 |

| FBS04x | 4 | 0.50 | 0.13 |

| FBS05x | 5 | 0.50 | 0.13 |

| FBS06x | 6 | 0.80 | 0.13 |

| FBS08x | 8 | 0.80 | 0.13 |

| FBS10x | 10 | 0.80 | 0.16 |

| FBS12x | 12 | 1.00 | 0.16 |

| FBS15x | 15 | 1.00 | 0.16 |

| FBS20x | 20 | 1.50 | 0.16 |

| FBS25x | 25 | 2.00 | 0.16 |

Characteristics

- For an electrical loom or harness, excellent metallic shield or screen.

- Simple installation and removal from prior.

- High expansion ratio and is extremely versatile.

- Optical coverage ranges from 85% to 95%.

- There are flat braids and metal braids with a central filler to stop the braid from deforming.

- Standard strands come in the letters "S," "T," and "N," which stand for copper that has been nickel-, tin-, or silver-plated.

Because of their multi-axial flexibility, round braid bonding leads have an advantage over flat braid bonding leads when it comes to managing system temperature or grounding electrical connections. It minimises the effects of electromagnetic interference and safeguards against electrostatic discharge.

Application

- Flying connections and electrical grounding both require metal braided.

- Used over cable bundles for both physical and electrical protection.